Flexible Processing for Complex Automation Tasks

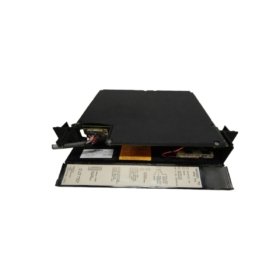

The IC697CPU731 serves as a capable central processor for GE’s Series 90-70 PLC platform. This module manages a versatile mix of up to 512 digital and analog input/output points. Furthermore, it supports real-time application control for demanding processes across various industries.

Programmable with Modern Windows-Based Software

Engineers configure and program this CPU using standard Windows-based development software. This approach provides an intuitive interface for creating, debugging, and documenting control logic. Consequently, system development and maintenance become more efficient for your engineering team.

Robust Communication and Expansion Capabilities

The IC697CPU731 communicates with other rack modules through the high-speed Series 90-70 backplane. It also supports control of remote I/O modules for distributed system architectures. Moreover, the CPU can handle extensive analog I/O configurations for precise process monitoring and regulation.

Comprehensive Technical Specifications and Performance Data

Below are the detailed technical parameters for the GE (Emerson) IC697CPU731 CPU module.

| Parameter | Specification |

|---|---|

| Manufacturer | GE Fanuc / Emerson Automation |

| Product Line | Series 90-70 PLC |

| Model Number | IC697CPU731 |

| Module Type | Central Processing Unit (CPU) |

| Module Weight | 1.06 lbs (0.48 kg) |

| Microprocessor | 80C186 |

| Maximum Discrete I/O | 512 Points (Any mix of inputs and outputs) |

| Maximum Analog I/O | 8000 Points (across the system) |

| Real-Time Control | Supported |

| Primary Communication Path | Series 90-70 Backplane |

| Remote I/O Control | Supported |

| Programming Environment | Windows-Based Software |

Enabling Large-Scale System Integration

With support for 8000 analog I/O points, this CPU manages extensive process control applications. It is well-suited for industries like water treatment, chemical processing, and large-scale manufacturing. Therefore, the IC697CPU731 provides a scalable foundation for both discrete and analog-intensive control systems.

Supporting Distributed and Modular Architectures

The ability to control remote I/O modules allows for flexible machine and plant layouts. You can place I/O close to sensors and actuators, which significantly reduces long wiring runs. This capability makes the IC697CPU731 ideal for applications spread across a large physical area.

A Proven Platform for Reliable Automation

Based on the robust 80C186 microprocessor, this CPU offers proven stability for continuous operation. Its architecture balances processing power with the deterministic performance required for industrial control. System designers continue to rely on the IC697CPU731 for upgrading and maintaining critical Series 90-70 based systems.

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat