Overview

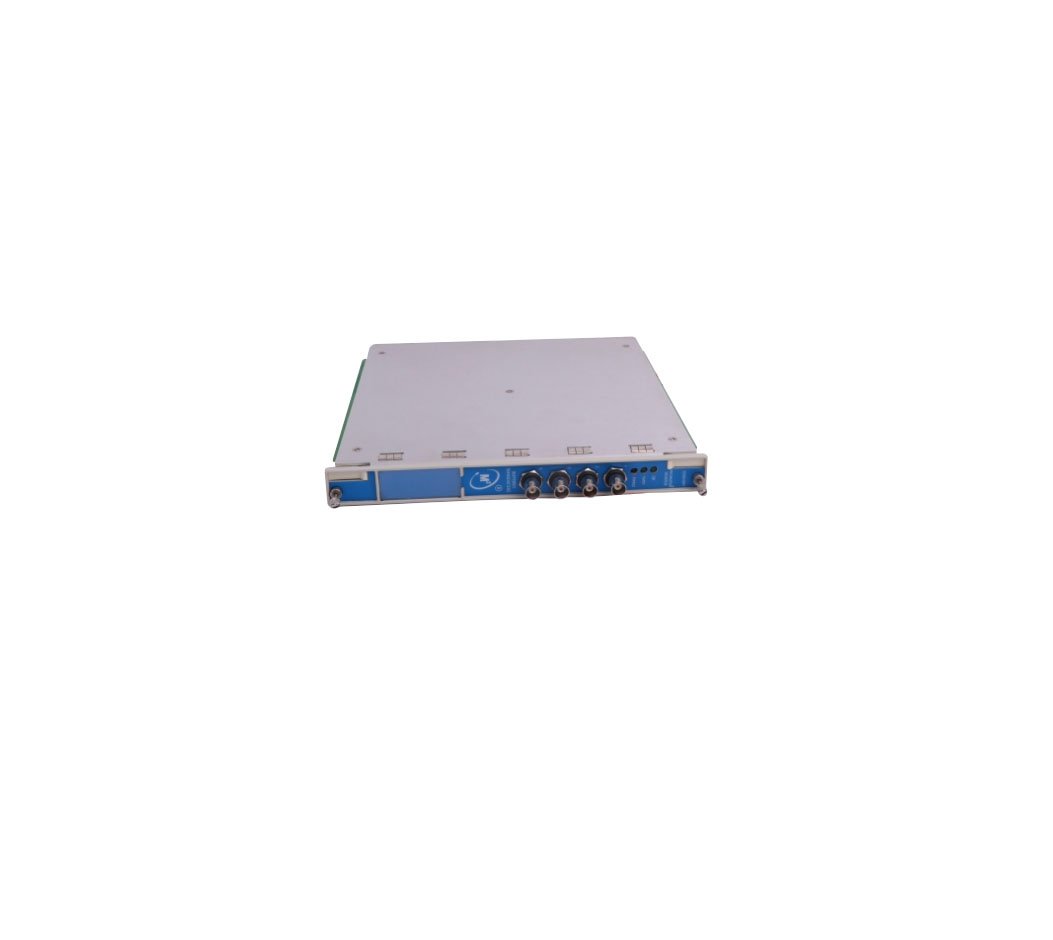

The Bently Nevada 3300/16-12-01-00-00 is a high-performance Dual Vibration Monitor designed for continuous, online machinery monitoring. It measures and monitors two independent channels of radial vibration and average shaft position (gap). The monitor accepts inputs from two proximity probes or Proximitor systems. This model is an essential part of the Bently Nevada 3300 Series Monitoring System. It meets the stringent requirements of the American Petroleum Institute’s API 670 standard, making it ideal for machinery protection applications.

With real-time monitoring capabilities, the 3300/16 Dual Vibration Monitor provides vital insights into machinery health, helping detect faults early and ensuring optimal equipment performance.

Key Features

- Dual Channel Vibration Monitoring: Continuously measures two independent channels of radial vibration and average shaft position, offering comprehensive condition monitoring.

- Early Fault Detection: Detects potential issues before they develop into major breakdowns, reducing the risk of costly downtime.

- Modular Design: The modular design allows easy integration with other Bently Nevada modules, creating a customized and scalable protection system.

- User-Friendly Interface: Designed for simple installation and maintenance, minimizing operational disruptions.

- Compliance with Industry Standards: Meets the API 670 standard, making it suitable for industries such as oil and gas, power generation, and manufacturing.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | Bently Nevada 3300/16-12-01-00-00 |

| Type | Dual Vibration Monitor |

| Measurement Range | 0-500 mm/s |

| Input Types | Proximity probes / Proximitor systems |

| Dimensions (L x W x H) | 19.8 cm x 16.2 cm x 10.8 cm (7.8 in x 6.4 in x 4.3 in) |

| Weight | 1.2 kg (2.6 lbs) |

| Certifications | CE |

Applications

The 3300/16 Dual Vibration Monitor is versatile and suitable for various industrial applications, including:

- Industrial Automation: Used in diverse automation systems to safeguard critical machinery.

- Power Generation: Provides vibration monitoring for turbines and generators, preventing excessive wear.

- Oil and Gas: Monitors pumps and compressors, ensuring continuous, reliable operation and reducing downtime.

- Manufacturing: Protects rotating machinery in manufacturing plants, enhancing operational efficiency.

Benefits

- Prevents Major Breakdowns: Early detection of faults leads to proactive maintenance, reducing the chances of unplanned outages.

- Minimizes Maintenance Costs: Identifying and addressing issues early ensures that machinery remains in optimal condition, lowering long-term repair costs.

- Enhanced Equipment Longevity: Continuous monitoring extends the lifespan of machinery by preventing excessive wear and tear.

- Improved Operational Efficiency: Accurate real-time data aids in making informed decisions, optimizing performance and safety.

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat